Let’s start at the end.

What happens to a luminaire after its job is done? Does it go to the Big Light in the Sky? Landfill? Does it get broken down into components that are recycled for parts or materials? Does it find a second life, reincarnated to shine on people somewhere else in the world?

We consider the answer to these questions ahead of the Biden-Harris Administration’s announcement , expected to coincide this month with Earth Day (20-22 April 2021), of the USA’s updated Nationally Determined Contribution (NDC) (the USA’s pledge to reduce greenhouse gas (GHG) emissions) under the Paris Agreement. The international treaty, signed in 2015, was the first global agreement under which all signatory countries committed to emissions reduction pledges (NDCs), which are required to become increasingly ambitious every 5 years. 2020 was one of those milestones, though the convention (known as COP 26) to discuss these pledges was delayed until 2021 due to COVID-19. Having recommitted the USA to the Paris Agreement in January this year, Biden’s announcement sets the stage for US leadership on climate change and restores the hope that this will increase global commitments to reduce emissions to net zero.

Writing from NYC, it is heartening to see federal priorities realign with the already ambitious decarbonization targets such as New York City Council’s Climate Mobilization Act legislative package. As part of the building industry, NYC is one of the highest emitting sectors globally that produces over 550 million tons of CO2 annually in the United States alone , lighting has the potential to play a critical role in delivering on these ambitions.

To that end, the conversation is live. Discussion centers around the two-step process required to make a difference – first being measurement of emissions to quantify the current impact and second being the application of that data to reduce emissions with specific targets. How the industry defines lighting products’ “end of life” will have significant implications for measuring the impact of fixtures in terms of GHG emissions over their full life cycle. This in turn will determine the industry’s success in reducing our carbon footprint.

Lighting designers, manufacturers, our partners in architecture, engineering and construction are reconsidering whether operational energy associated with the “Use” phase of a luminaire’s life should continue to be the sole focus of the industry’s efforts to contribute to net-zero carbon emissions targets. Historically, metrics and codes focused on energy consumption of buildings, with energy-efficient LED technology becoming pervasive and Lighting Power Density (watts per square foot or square meter) being a key metric for energy-saving standards. However, consideration of full life cycle emissions, or ‘embodied carbon,’ has become a critical new area of focus.

Embodied Carbon quantifies the global warming potential (GWP) of a product measured in emissions of CO2e attributed to the materials and energy used in the construction and maintenance of buildings. This includes processes of raw material extraction, manufacturing, transportation and installation to produce a luminaire. In addition, the carbon emissions associated with deconstruction, transportation, disposal and waste processing of fixtures at their end of life are measured. Operational Carbon refers to the GWP attributed to the operation and use of the building, being electricity used to keep lights on. Architecture 2030 estimates that by 2050, embodied carbon will form 49% of global carbon emissions from new construction compared with 51% from operational carbon. It warrants attention at the least for verification, and at most for remedial action.

A 2019 Carbon Leadership Forum study of a WeWork commercial office space found LED fixtures to be the second highest MEP item for embodied carbon. The majority of this was attributed to the Production phase of a fixture’s life cycle; 194 kg CO2e/m2 from manufacturing (Stage A), compared with a credit of -14 kg CO2e/m2 for endof-life disposal (Stage C). The results prompted further investigation into the embodied carbon implications of key fixtures and layouts.

At a recent LEDucation seminar presented in March with my colleague Elaine Cook on embodied carbon in lighting, a poll taken in a room of 316 attendees found 94% of participants would use embodied carbon information if available. Further, 97% of participants agreed the lighting industry should have a consistent standard to data collection and Life Cycle Assessment of fixtures. The results were compelling and supported by professionals from both the design and product side of the industry – 48% of participants were designers while 34% were from product (21% of whom identified as manufacturers and 13% as sales representatives).

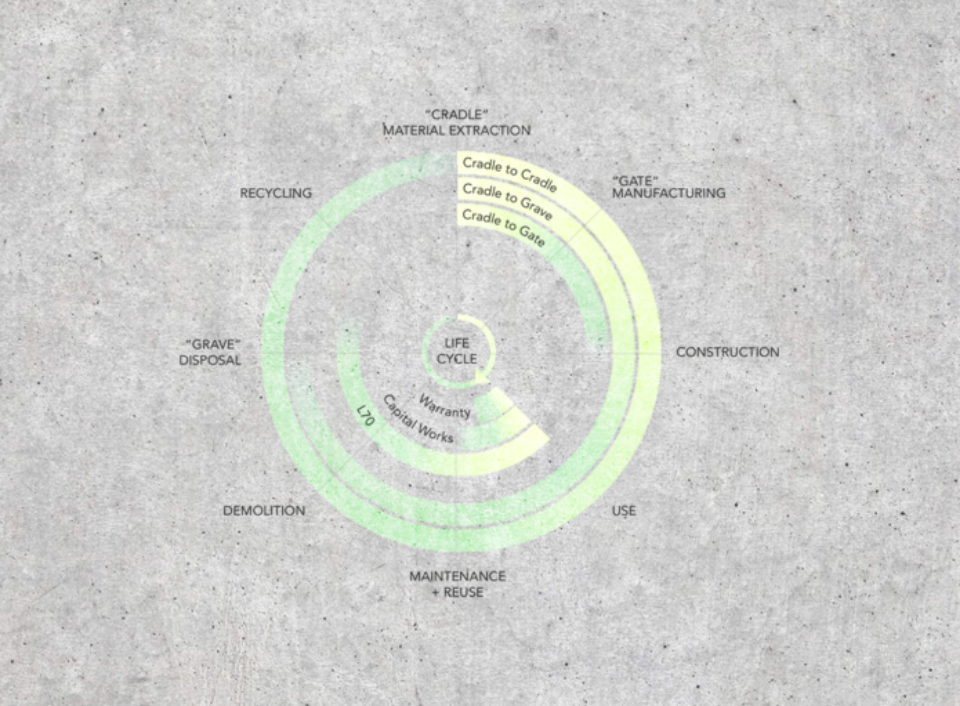

Currently, there are parallel systems existing to determine the relevant life of a product, each of which will give a different measure of carbon emissions. Traditional approaches underestimate impact by acknowledging operational carbon alone. These include:

- Manufacturer’s warranties that provide a conservative estimate of the functional life of a luminaire and lead to premature disposal and excess waste if followed strictly.

- Actual replacement times based on turnover and capital improvement cycles of commercial spaces that shorten the effective life of a fixture.

- L70⁸ which defines the length of life in terms of the number of hours taken for an LED fixture to get to 70% of its original output.

- At the same time, emerging systems of life cycle analysis investigate wider spans of a luminaire’s existence. These include:

- Cradle to Gate that focuses on production of a fixture to the point of leaving the manufacturer’s factory and excludes accountability for usage and end of life implications.

- Cradle to Grave that studies life cycle phases from the initial raw material extraction to disposal. This has been the main approach for Life Cycle Assessment (LCA) analysis of internationally recognized data reports called Environmental Product Declarations (EPDs).

- Cradle to Cradle that captures the circularity of materials and components with an emphasis on recycling and reuse stages that continue the life of the luminaire or its parts diverted from disposal.

The varying approaches highlight the need for greater industry consensus to avoid duplicating efforts or creating competing standards despite allied intent. We must decide which metrics and Green Building rating systems best convey the circularity of materials and products. Also, we must consider which interpretation of LCA methodology will provide most reliable data for decision making.

The GreenLight Alliance formed this year as an international community of individuals, businesses and institutions within the lighting profession to facilitate this dialogue. Its aim is to support knowledge share, systems and efforts in circular lighting design and the circular economy as well as develop a reliable set of industry standards that are universally recognized, trusted and sought-after. The network is growing the conversation between designers, manufacturers, educators, media, compliance schemes and associations, and all participants are taking leadership positions to evolve legacy frameworks and metrics.

In the dearth of regulatory requirements, corporate leaders in partnership with dedicated designers are making moves to adopt internal policies that address embodied carbon and circular economy principles. Manufacturers such as We-Ef recently republished Environmental Product Declarations initially prepared as early as 2013, including the GWP of select outdoor fixtures. French luxury brand conglomerate, LVMH, in conjunction with over 25 of their lighting suppliers, developed Lighting For Good – a rating system for lighting products that encompasses life cycle impact including usage. Their voluntary action suggests demand for certain fixtures will be influenced by lighting designers who value the data provided by manufacturers invested in understanding and evolving their product design for material and production efficiency as much as performance efficiency and longevity.

Returning to the question “What happens to a luminaire after its job is done?”, the answer we give today will influence the degree of the lighting industry’s success in achieving decarbonization goals of tomorrow. It brings another lens to the question of “What is successful and impactful design?”. Wherever our concept of the life and death of a luminaire rests, as we work together on agreeing best practice approaches to measuring and valuing the life of our luminaires, it is our decisions that will live on.

This article was originally featured in the April issue of designing lighting (dl)