Figure 1 Color Vector Graphic (courtesy Nichia)

When I say “90 CRI,” you hear the phrase, you process it, and you summon your past experiences with 90 CRI. You may reference additional biases, but you instantaneously arrive at an understanding of what I said—a common ground upon which to communicate. So much of what we prefer and promote as lighting professionals is based on experiential feedback. Our impressions are formed by how light looks on our skin or how it compares in a side-by-side inspection with reference objects. Yet, many facets of the lighting specification process are abstract. We rely heavily on software programs during the specification process, and when communicating color, we rely on metrics. It seems like now—especially during the pandemic, when our travel is curtailed, when conventions are sparsely attended—we are forced to rely on proxies for first-hand experiences that we would normally enjoy. And despite our personal visual differences, we need a common language that we can all agree on because communicating color is at the core of what we do as lighting professionals.

CIE R a —what we refer to colloquially as “CRI”—has been with us for over 50 years. Prior to the CIE adopting IES TM-30 Rf in 2018, it was the only color rendering metric recognized by an institutional authority. Most specifiers recognize the untenable limitations of CRI. Two light sources with the same CRI score, for example could render object colors quite differently. CRI is computed as an average using only eight reference colors, and that small set of reference color leads to a high-degree of imprecision. Yet, when asked, many lighting pros are not ready to totally embrace the alternative, TM-30. Why is that? The answer is different depending on the perspective of the various shareholders.

Specifiers

The reason most lighting specifiers are reticent to back TM-30 is a belief that it is too esoteric and therefore too difficult to teach to clients. Realistically, almost all of the metrics we employ in our industry are abstruse. Most lighting professionals would be hard-pressed to teach concepts like luminance, coefficient of utilization or MacAdam ellipse, yet we rely on these metrics daily. They appear on specification sheets and in our submittals. We don’t have to teach them; they just are part of the background of our workaday lives as lighting professionals.

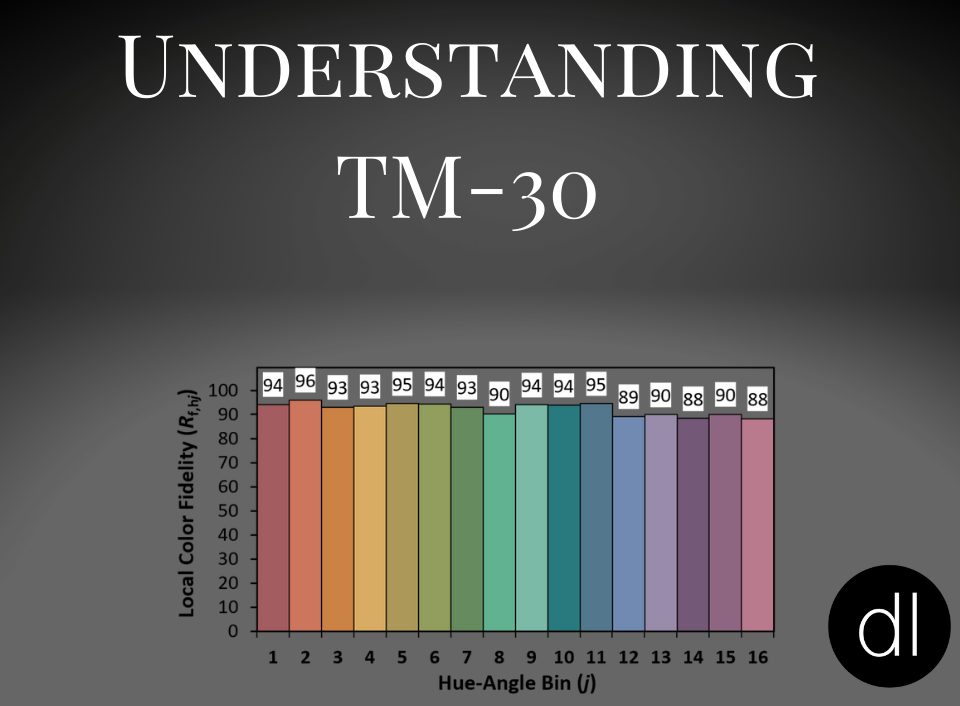

TM-30 is a tool—just like any other metric, and we simply need to know how to employ it. It may feel large in scope, but the information you need—even simple information is readily available. Take Fidelity as an example. CRI is based on the average of how a light source renders eight color samples vs. a reference light source. R f , TM-30’s Average fidelity measure, uses 99 colors. That’s 91 more than CRI! And, those colors were methodically chosen from a large sets of color having uniform distribution in color space and wavelength space. If we do nothing else as an industry, we should embrace R f , as replacement to CRI. R f appears in the upper left-hand corner of the Color Vector Graphic (figure 1) generated by the IES TM-30 calculators, which is information—available at-a-glance that should easily fit on every manufacturer’s cut sheets.

Value engineering is another reason to embrace TM-30. In a time when you have to write a specification like a legal document in order to avoid 11th hour swaps, TM-30 with its specificity provides a template for customization—a way for the lighting designer to drive value by setting specific attributes of color rendering. It provides a unique opportunity for call-outs for minimum requirements, which, in turn, leads to possible specification lock. The details keep the vultures at bay.

Manufacturers

A review of the spec sheets for leading lighting manufacturers shows a reluctance to provide TM-30 information. This creates a bit of a catch-22 scenario. Designers point to the lack of information from equipment manufacturers as a reason not to use TM-30. With TM-30 enjoying widespread institutional acceptance, it is difficult to understand why there is not more demand for reporting. It doesn’t require anything more than the spectral power distribution (which manufacturers already have), and the output is practically instantaneous.

Said another way, the manufacturers that master it now will be those that lead the industry when color-mixed LEDs have the crown.

Let’s face it: CRI gives manufacturers a place to hide so-so color quality, but there is also an issue of differentiation among these same manufacturers. The features of a 2” slot fixture, for example, can be annoyingly similar from manufacturer to manufacturer. TM-30 conversely provides firms with the ability to differentiate. Those firms that gravitate toward the ability of TM-30 to enhance their offering will be the same firms in the future innovating with color as color mixing LEDs and spectral engineering evolve. Said another way, the manufacturers that master it now will be those that lead the industry when color-mixed LEDs have the crown.

Consumers

Wattage equivalency appears to be the only metric consumers understand, and with incandescent phase-out, even that is fleeting. Energy star labelling did a good job of demystifying CCT, but in order to capture general color quality, we’ve relied on CRI with all the baggage we’ve previously mentioned. TM-30’s color rendering graphics provide a consolidation of the information consumers need in order to make an educated decision. There is the Fidelity score, Rf that appears on the Color Vector Graphic that can be a proxy for quality. In addition, we can provide on package labelling Local Fidelity Charts (figure 2). A homeowner who is painting their walls a certain color, for example, can reference the Local Fidelity Chart and find the best light source for their palette.

Figure 2 Local Fidelity Chart (courtesy of Nichia)

Consumers are capable of changing behaviour. What is critical, however is consistency in metrics. TM-30 is a robust framework and has an infinite shelf life because the outputs can be modified to meet changes in lighting science and technology. There was a time when CRI was “good enough” to distinguish between the three fluorescent lamps on the market. But now that LEDs have so much spectral variability, CRI is not useful. As such it becomes ideal for consumers, who throughout these changes will be looking for tried and true metrics that they have experience with to show them the best choices.

There is a learning curve with TM-30, but it isn’t nearly as steep as lighting professionals believe. Some simple updates to LC curriculum and certification/testing can create mandates to learn the information. Once learning increases at large that information becomes table stakes. Every lighting pro will learn it to stay abreast. Color is a huge part of what we do as lighting professionals and we need a common language from which to share information. CRI is out; TM-30 is in. It’s time we all catch up.

This article was originally featured in the October issue of designing lighting (dl).